Duta Firza has been a trading business circa 1978 for instrumentations and control systems. It is essentially the core of this company, as trading was the only line of business that Duta Firza worked within at the beginning.

This might show how Duta Firza's trading division is the most experienced and practical, with years of experience. We are proud to recognize that we have worked by working with distributors.

Ashcroft is the leading source of temperature and pressure instrument solutions for critical Process and Industrial/OEM (original equipment manufacturer) applications across the globe.

Our extensive industry experience and customer-driven approach allow us to provide solutions that fully accommodate the needs of your critical processes and applications ensuring accurate and safe operations.

Our Products

Yamari Industries Limited is an exclusive distributor of temperature instrumentations based in Japan, and in which Duta Firza has been trading with. They provide various types of measurement instruments such as petrochemical and semi-conductors. In trading with this company, Duta Firza is able to keep up with the technological advacements in order to make the process of collecting and finding oil, made simpler and more efficient.

As on today YAMARI has expanded into the reaches of the globe, with factories and offices in Singapore, Korea and India, representative offices in China, Taiwan and many other countries. Our company is also certified under ISO 9001, ISO 14001 & ISO 18001 and has been pursuing green procurement standards for preventing pollution in our global environment.

Our Products

Autrol Smart Transmitter products, manufactured by Duon System, harmonize with all instruments at the field. We have been finding a way to have the best measurement solution in world instruments market.

Duon System was established on May in 1989. Since then, we had successfully performed for DSC(Distribution Control System) with more than 70 projects. However, we have focused on developing Smart type, which is core part of field instruments.: Differential, Gauge, Absolute, Temperature and GWR(Guided Wave Radar) transmitters with our own technology as named Autrol.

Autrol Smart Transmitter has performed all sorts of applications at more than 45 countries successfully with high class of international quality systems in field along with universal protocol, international certificates and regulations. The results have satisfied End-users and we are very proud of both Duon System and Korea instrument market because no one had a result like Duon System for Autrol Smart Transmitter in Korea.

Our Products

SAMIL is a various level and flow elements manufacturing company that bring technology and engineering together to provide high quality products to customers in the petrochemical, Oil and Gas refinery, Waste water disposal facility, Nuclear/Thermoelectric power plant, etc.

Our Products

Qublock Technology has proven expertise for providing custom-made valve solutions as well as standard products with innovative and advanced technology for perfect flow control, ease of operation, simple in-line maintenance, and long service life.

Based on strict Japanese technology and know-how Qublock engineers have gained through years of experience and study, Qublock focuses on severe applications requiring solutions to high temperature, high pressure, high-cavitations, high-cycle, corrosive and erosive situations with a tight shutoff and low emission.

With an international presence, Qublock combine our technical know-how and engineering expertise under the Head Quarter including of technical design, quality control and sales operation in Japan and the main production basement and sales branch operation in South Korea.

As a leader in valve technology, Qublock Technology provides prompt and clear solutions to any difficulties that a customer may face in their plant.

Our Products

Flowbus Corporation was founded in 2004 with the aim of manufacturing reliable heavy duty valve actuators and providing innovative valve automation packages to the global energy and process industries.

Since then we have accumulated an excellent reputation with an impressive track record in critical applications within offshore and onshore like oil and gas, power generation, chemical, desalination and environment applications.

From feasibility studies, engineering, designing and manufacturing to maintenance, Flowbus Corporation is recognized as a leader in the valve automation market creating enhanced value for our customers.

Major business areas include design and manufacturing of industrial valve actuators. Also the fabrication of valve control and safety systems enabling our customers to improve their performance while lowering total installed cost.

Flowbus Corporation aims to continue delivering high quality products and services to our customers worldwide.

Our Products

Sterling Sensors is a market leader and has over 45 years’ experience in the manufacture of bespoke temperature instrumentation. We specialise in the production of thermocouples, RTDs, hand held probes and other temperature sensors. We also offer a calibration service and all calibrations are supplied with UKAS traceable certification.

Our technical engineers are vastly experienced in solving customer application problems using our modern facilities and on-site machine shop. We have the ability to manufacture bespoke solutions to meet with the requirements of some of the most complex measurement and control applications. Such expertise allows us to compete in a vast range of markets including aerospace, food, pharmaceuticals, energy, plastics and metallurgy, some of the most stringent industries in manufacturing. We are an ISO 9001:2008 registered company and our quality management is audited on a yearly basis by IMS.

Our Products

Rotork Instruments are specialist manufacturers of products for flow control, pressure control, flow measurement and pressure measurement. Our solutions are trusted wherever there is a need for high precision and reliability, including pharmaceutical, biomedical, oil & gas and manufacturing industries.

We have production facilities throughout the world, complemented by a large network of distribution and support centres.

Rotork Instruments is proud to offer a diverse range of products which serve many different duties in a wide variety of applications. We also offer a factory customisation service, to create one-off units to meet specific needs.

Our Products

Air Hydro Pumps Incorporated was formed in California to specialize in the supply of air driven high pressure hydraulic pumps and power units to customers located throughout North and Central America. Our products are well proven and are manufactured right here in the USA. They are available on short delivery and competitively priced. They have been developed for and are mainly used for pressure testing however they can also be used for operating bolt tensioners, hydraulic jacks and cylinders.

They especially come in to their own whenever hydraulic power is required on site in inaccessible places. Being air powered they can be used in fire hazardous areas without the need for expensive flame proofing. Here at Air Hydro Pumps Incorporated our goals are simple, we aim to supply reliable, fit for purpose products on time and at a reasonable cost.

Our Products

Even though the orifice plate has a disadvantage of permitting a greater pressure loss than other differential pressure type flow meter such as flow nozzle and venturi tube, etc., the orifice plate is popularly used for flow measurement due to high reliability, low cost, easy manufacturing and simple shape.

As for bore type of orifice plate, there are Concentric, Eccentric, Segmental and Quadrant Edged types, and sizing calculation and design for the orifice plate are based on the standard codes of ISO-5167, ASME MFC-3M within a tolerance in compliance with these ISO & ASME Standards.

Since its establishment in 1968, JOKWANG I.LI CO., LTD. with its JK trademark has put every effort in pioneering and specializing as one of the leading valve manufacturing companies. Its devotion has concentrated especially in the area of safety relief valve, pressure reducing valve, stop valve and steam trap.

With almost half a century of experience, we have earned over a good reputation for quality, reliability, reasonable price and excellent performance.

We determined to contribute to serve your need for your heat control and energy saving effort through our precision design, strict testing, and precision processing. Your kind inquiries would be much appreciated, and we will do our best to give you our business suggestions on them, which can be competitive in your market. In closing, we promise for our continuous endeavor, for more research, and for development work to pay back your positive supports and encouragement.

Our Products

It is a great pleasure for us to take this opportunity to introduce HAWKSINDUSTRY Industrial Co., Ltd to our customers.

HAWKSINDUSTRY Co., Ltd has members have a great store of knowledge and knowhow to design and manufacture the products with an abundance of site experiences for installation.

With our technical experience and capability as well as our unflinching spirit of devotion to the clients concerned, we would like to assure you that we will do our utmost to execute any designated project at the most economical price and in the shortest span of time, if and we are granted an opportunity to serve you.

Our Products

Evoqua and Xylem - two water technology leaders - are now one.

Together, we bring uniquely powerful capabilities to solving the world’s greatest water challenges. Uniting our complementary approaches, products, and expertise, we enable our customers to dramatically improve the way water and wastewater is used, managed, conserved, re-used and returned to nature.

Our Products

SmartMeasurement™ (SMC) was established in 2002 as a supplier of ?ow measurement instrumentation.

The company, headquartered in the United States with manufacturing operations in both the U.S. and China, provides an industry leading array of flow measurement solutions that include electromagnetic, ultrasonic, thermal mass, vortex, turbine and positive displacement technologies.

Our Products

Since 1989, WOOSUNG FLOWTEC Co.,Ltd has produced all kinds of strainers, ?lters and customized products and we’ve done our best to meet customer’s needs and satisfactions with three mottos - “Best quality”, “Reasonable price”, and “On time delivery”.

As inexpensive insurance, STRAINERS from WOOSUNG FLOWTEC Co.,Ltd . have widely applied and utilized in Onshore plant(Oil & Gas industry, Petro-chemistry, Power Plant, Fresh water, unit, etc,) O?shore plant (FPSO, Drill ship, Platform, etc ) WOOSUNG FLOWTEC Co.,Ltd has done our best to globalize by export our products to the world-wide.

Our Products

KHI consists of senior engineer, operator with plenty of experience to satisfy customer's all needs.

As one the leading expansion joint manufacturers. KHI proudly supplies a variety of expansion joints to many leading companies in the power plant, utility, petrochemical, re?ning, shipbuilding, OEM and virtually every other industry. KHI can help you specify and layout the correct joint for any application. All expansion joints are designed using software developed by KHl's engineers.

Our Products

Especially JAIN TECHNOLOGY makes fully digitalized various kind of ultrasonic flowmeters for liquid and gas. Also, JAIN TECHNOLOGY has CERTIFIED CALIBRATION LABORATORY for liquid flow in accordance withthe recognized International Standard ISO/IEC 17025:2005.

JAIN TECHNOLOGY provides the total solutions of the ultrasonic flow measurements from planning and design, through to manufacturing, installation and commissioning. We deliver a complete range of flow measuring services, as well as specialized assistance in a range of ultrasonic flowmeters.

In addition, JAIN TECHNOLOGY involved in DEFENCE projects using sound localization technologies for sniper localization and bullet detection.

Our Products

No.1 manufacturing company Sentech ENG

SentechEng Co.,Ltd is a quality manufacturer of instrumentation and control equipment in the Korea and Southeast

Asian region. Established in 2007 SentechEng dedicate to develop of the field of measurment. As a result SentechEng has transformed into a truly recognised company with the reputation of providing quality instruments, material product development and repairing services as well as manufacturing. As an ISO 9001, CE certified company, we commit ourselves to bring out the very best of our quality products and services to our customers. In 2017, SentechEng has been awarded with the Prestigious Korea SMEs.

As a one-stop instrumentation house, SentechEng provides wide range of measurement and control products

ranging from temperature, humidity, pressure, flow, calibrator, explosion proof.

With of experience in instrumentation business and a strong technical support team, you can be assured of our services. we have manufacturing facilities to custom-make temperature sensors, thermowell, wire to meet your requirements. Also our competent agency provide on-site technical meeting.

Our Products

With Precision, For Environment

Established in 1989, DONGWOO OPTRON has succeeded in developing the first flue gas analyzer in Korea based on many years of experience in spectroscopy.

With continuous effort and investment to improve the quality and performance, DONGWOO OPTRON has achieved total sales of more than 2,035 units of flue gas analyzers and established itself as one of the leading flue gas analyzer manufacturers.

In pursuit of Accurate Analyzer with User-friendly System, DONGWOO OPTRON will continue strive to achieve customer satisfaction and trust in global market.

Our Products

Since its establishment, the KOSO group has developed a diverse range of high-quality control valves of diversified types, greatly contributing to the implementation of process automation (PA) in various industries.

In 1976, KOSO started to develop, manufacture, and sell automation systems utilizing the abundant experience and know-how earned by that time. Today, even stronger from strategic acquisitions, KOSO is able to offer a complete line of automation systems, including sensors, controllers, and computers.

KOSO stands ready to meet every customer need with the best products available as they strive to equip themselves with the total automation systems of the next century.

Our Products

Only recently has Duta Firza become a manufacturer for pressure and temperature instrumentations. Working together with ASHCROFT, the facility located in Sentul - Bogor 16810, is striving to fulfill the high demands of these instrumentations.

Not only does it speed up the process of transportation, but it provides the fact that these instrumentations, based on a design and quality assurace system made by an American company, are indeed made 100% locally in Indonesia. Duta Firza is aiming to satisfy customers this way.

PT Duta Firza Technologies (Duta Firza), was appointed in 2010 to grow sales in Indonesia. One important factor in the success of competing in this region, is the need for quick delivery and readily available stock, as well as meeting governmental requirements for local content.

Ashcroft and Duta Firza joint up to set up a local assembly operation in Jawa Barat to assemble the Ashcroft products

Special Projects come as an additional division to our company.

Site Location :

Kota Makassar | Jl. Lantebung | Kec.Tamalanrea, 30 Minute from Makasar City

Total Area : 10 Ha.

Special Projects Division:

- Awarded in 2010 as a BOO Contracts with Pertamina

- Project Value is USD 80m

- Contract Period of 10 Years

- Capacity 10,000MT

Facilities including :

- Onshore: tanks, filling stations and offices

- Offshore: Jetty, 6km subsea pipeline

Status: In operation

Expansion New Business Related to Energy – Special Projects

- Petrochemical

- CNG Facilities

- Power Plant

Penetrating Core Competencies

- EPC

- Trading

- Upstream

Expansion Planning

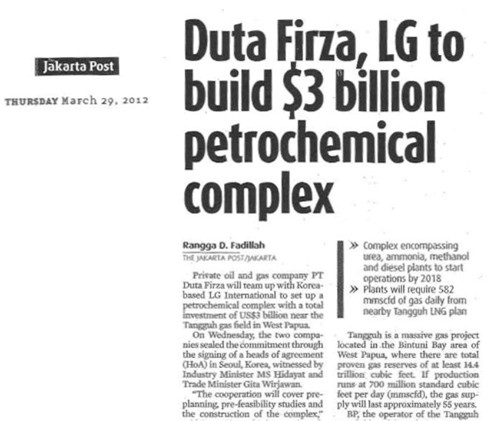

- Petrochemical Plant with LG International in Papua utilising gas from BP Tangguh with feed gas amounting 90mmcfd

- 15MW Gas fired Power Plant in East Kalimantan

- CNG Facilities in Central Kalimantan storing gas amounting 4mmcfd

- Acquiring another upstream oil and gas fields

Petrochemical Project

- Methanol Project

- Capacity: Methanol 1,000,000 t/y (3,000 t/d)

- Feedstock: Natural Gas (appox.91MMSCFD)

- Budget: U$ 1,200 ~ 1,300 mil.

- Construction Period: 36 months

- Financing: Equity + Project Financing

EPC Penetration

Upstream Projects

- Tangguh Project in Bintuni Papua for development of train 3 and 4 LNG Plant

- Masella Block for FPSO and offshore facilities

- Conoco Phillips

- Chevron Makassar

As an EPC contractor as well, Duta Firza has been delivering EPC projects which can date back to 1993. EPC projects were conducted and has been completed in certain regions of Indonesia, such as Makassar, Kalimantan, Surabaya, and Bali.

The EPC division would consist of two categories; engineering and project management. Duta Firza has delivered contracts with large and major oil and gas companies such as Pertamina, Shell, and Indonesia Bulk Terminal.

A contract with PT. Shell Indonesia of 1 year, requires the construction of a tank farm which then indicates the needs of construction of tanks of different sizes as well as the foundations and drainage systems that must go with it.

In 1993, Duta Firza delivered an EPC contract with PERTAMINA, lasting for 3 years and was an EPC of an oil transit terminal in Amuk, Bali. This contract required Duta Firza to expand the needs of the client within this contract, which then includes an EPC for civil works (such as preparing the land, mooring the dolphins, supporting facilities, etc), an EPC for mechanical works (such as diesal storage tanks, petrol storage tanks, product pump stations, etc) and an EPC for electrical instrumentation and automation works.

In 2013, through PT GPS, Duta Firza was awarded for the Provision of topsides EPC for Bukit Tua FPSO projects. The project enriched Duta Firza’s portfolio and strengthened full EPC capabilities in advanced fabrication technologies.

In this way, the EPC division of Duta Firza needs to be divided into two categories, in order to effectively divide the tasks and carry out the contracts with professionalism. The engineering team focuses on the design and process of the materials and facilities needed for the EPC, and thereby includes all aspects; mechanical, civil, and electrical. The project management team focuses solely on the planning, scheduling, cost control and documenting of the EPC.

Construction of Berthing Facility and Jetty Piping, Pulau Laut Oil Terminal for PT. Indonesia Bulk Terminal 2009 – 2010

- Project Owner : PT Indonesian Bulk Terminal (IBT)

- Project Values : USD 15m

- Project Duration: ± 1 years

- Project Vendor : PT Intimarindo Primacon - PT Duta Firza Consortium

Scope of Work : To Provide Engineering, Procurement, and Construction of Berthing Facility and Jetty piping, which includes of :

Construction of Berthing Facility :

- 1 unit Jetty Loading plat form with size 15m x 30m

- 2 unit Breasthing Dolphin with size 9m x 10m x 2m

- 4 unit Mooring Dolphin with size 7m x 7m x 2m

Construction of Jetty piping: Piping construction started from battery limit to Loading Platform

Additional Scope of Work to the contract for Construction of Tank Farm, Tank Foundation and Tank Construction for Gresik Terminal, Surabaya (Package 1) 2008 - 2009

- Project Owner : PT SHELL Indonesia

- Project Values : USD 5m

- Project Duration: ± 6 month

- Project Vendor : PT Duta Firza - PT Intimarindo Primacon - PT Bangun Cipta Kontraktor Consortium

- Scope of Work :

- Gravel filing, sub base, HDPE membrane etc. in Tank Farm.

- Construction of External and intermediate bundwalls

Construction of Tank Farm, Tank Foundation and Tank Construction for Gresik Terminal, Surabaya (Package 1) 2008 – 2009

- Project Owner : PT SHELL Indonesia

- Project Values : IDR 57b

- Project Duration: ± 1 years

- Project Vendor : PT Duta Firza - PT Intimarindo Primacon - PT Bangun Cipta Kontraktor Consortium

- Scope Of Work : Construction of 6 units of 5,000m3 cap tanks, Construction of 2 units of 1,000m3 cap tanks, and laying down tank foundations and drainage system

To Provide Engineering, Procurement, Construction and Commissioning of six (6) numbers of 5 kT Vertical Storage Tanks which includes, but not limited to the following:

- Detailed Engineering Design inclusive of all calculations, meeting all specifications as required by company

- Detailed Construction Drawings

- Supply of all material for completion of the work scope

- Construct and commission all facilities :

- Carry out construction of tank farm, tank foundations, bund walls and associated civil and structural works as per detailed design by EPCM consultant

- Carry out all required testing and verification services to ensure compliance to all design codes

- Provision of as-built drawings and documentation

The dimension of Six (6) numbers of 5 kT Vertical Storage Tanks, are :

- 3 gas oil tank with size : 23,2 Ø x 15,0 m Ht (type of tank : column supported fixed cone roof tank)

- 3 ULG tank with size : 23,2 Ø x 15,0 m Ht (type of tank : column supported fixed cone roof tank)

1x1000 MT LPG Tank Construction Project in Labuhan Amuk-Bali 1995 – 1997

- Scope of Work : Detail Engineering, Procurement, and Construction

- Project Owner : PERTAMINA UPPDN V Surabaya

- Project Values : Rp 3b + USD 1.7m

- Project Duration: ± 2 years

- Project Vendor : Inti Duta

The dimension of 1x1000MT LPG Tank, is :

- ASME Sec VIII, Div 2 : ID = 17,03 m and t = 46 mm

- 8 Column diameter 24”, h = 12 m, schd.40 (tmin = 17,5 mm)

Fuel & LPG Transit Terminal Coonstruction Project in Labuhan Amuk Bali 1993 – 1995

- Project purpose : to supply fuel and LPG at Bali, NTT, NTB and maintain the stock purchasing

- Scope of Work : Detail Engineering, Procurement, Construction, Start-up & Commissioning

- Project Owner : PERTAMINA UPPDN V Surabaya

- Project Values : IDR 43b + USD 10m

- Project Duration: ± 2,5 years

- Project Vendor :Duta Firza-Intimarindo Primacon-Citramuda Nusasarana-Benua Mekanika Consortium

The Exploration & Production (E&P) division manages the upstream oil and gas. Our most prominent contract recently, has been with Pertamina. Our main E&P Projects took place in Kalimantan, Bangkudulis (KSO) and Bunyu Tapa (KSO).

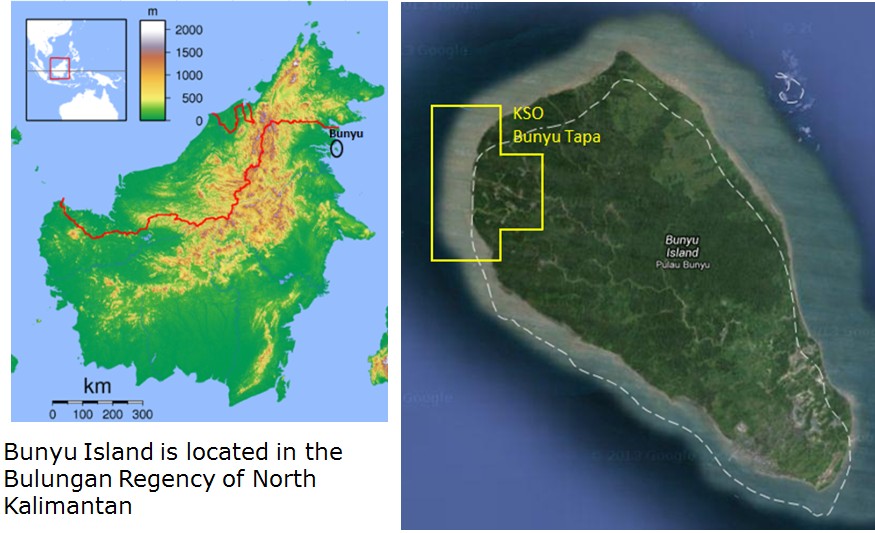

Bunyu Tapa KSO – North Kalimantan

- Bunyu Tapa Located in North Kalimantan

- Bunyu Area has produced 300 MM BOE since early 1900’s

- Current production on the island is approximately 6,000 BOPD and 10-12 MMSCFD

- Initial well production rates anticipated to be 1-3 MMSCFD, 30-50 BOPD

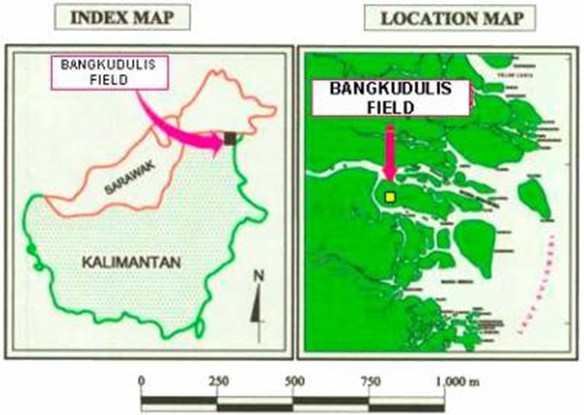

Bangkudulis KSO – East Kalimantan

- Located in East Kalimantan

- Recoverable oil reserves is 20m bpo

- More than 80bscf

Duta Firza has provided computer equipment (software and hardware) in the oil and gas market. Providing computer services does not have any direct relevance to the oil and gas industry, however being able to fund and help another oil and gas company would, in hopes, improve relations. In this way, Duta Firza does not only think of securing its future economically and financially, but also by creating close associations with others that can prove to become convenient, in the future.